Orbsoul Aerial Gear - Batch Break Testing

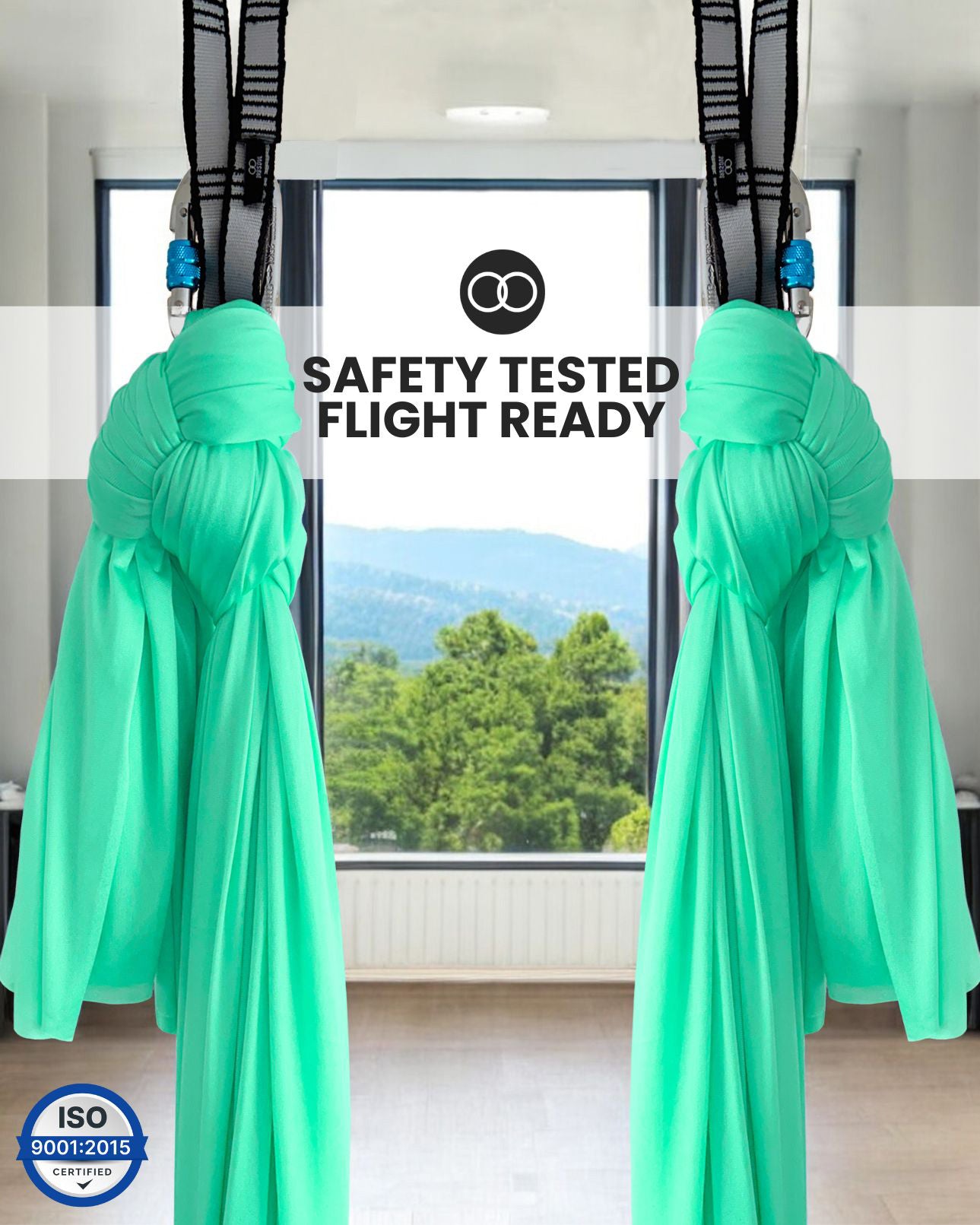

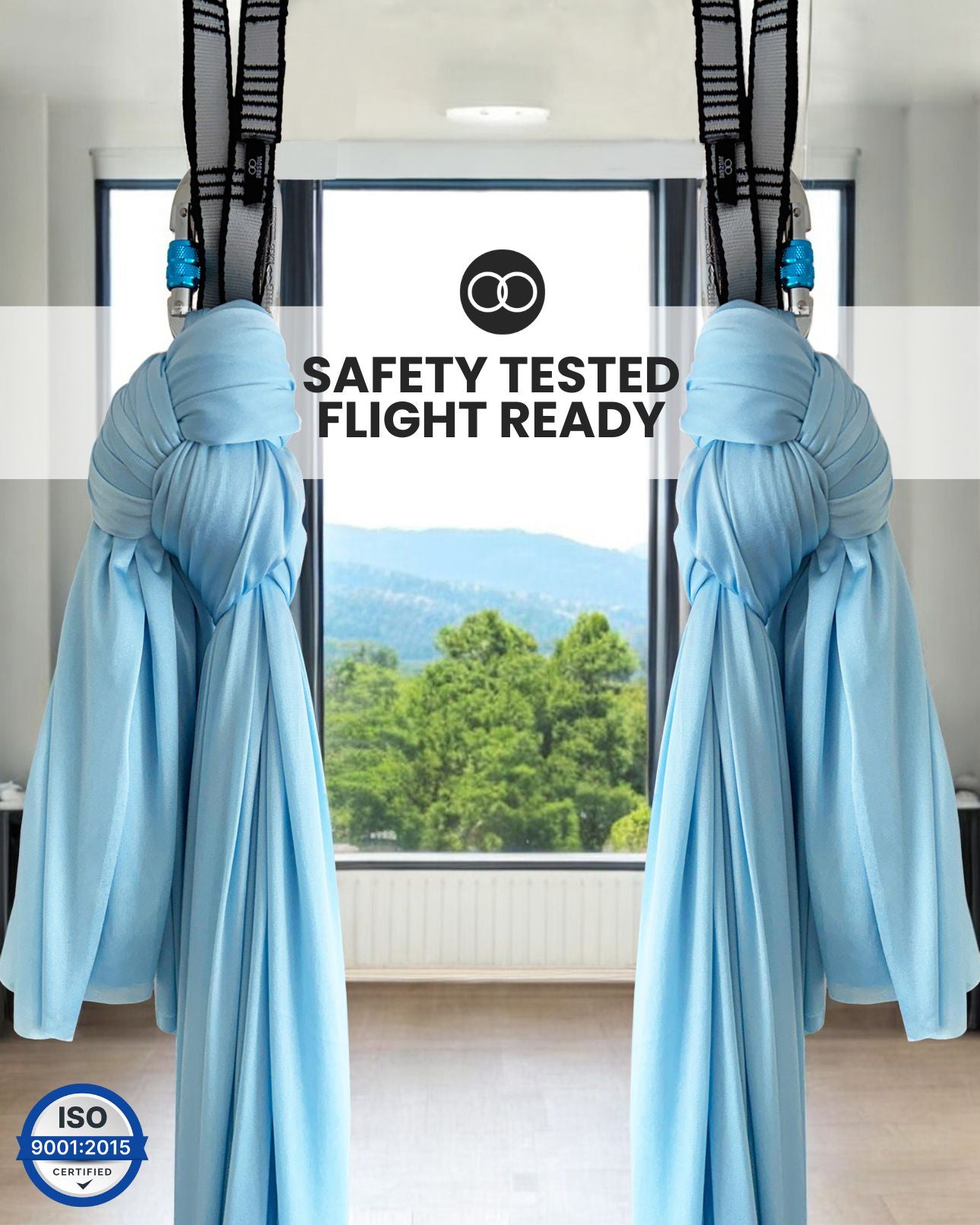

Your gear and continuous testing

To ensure our manufacturing process produces consistent high quality gear, we break test every batch of gear we make.

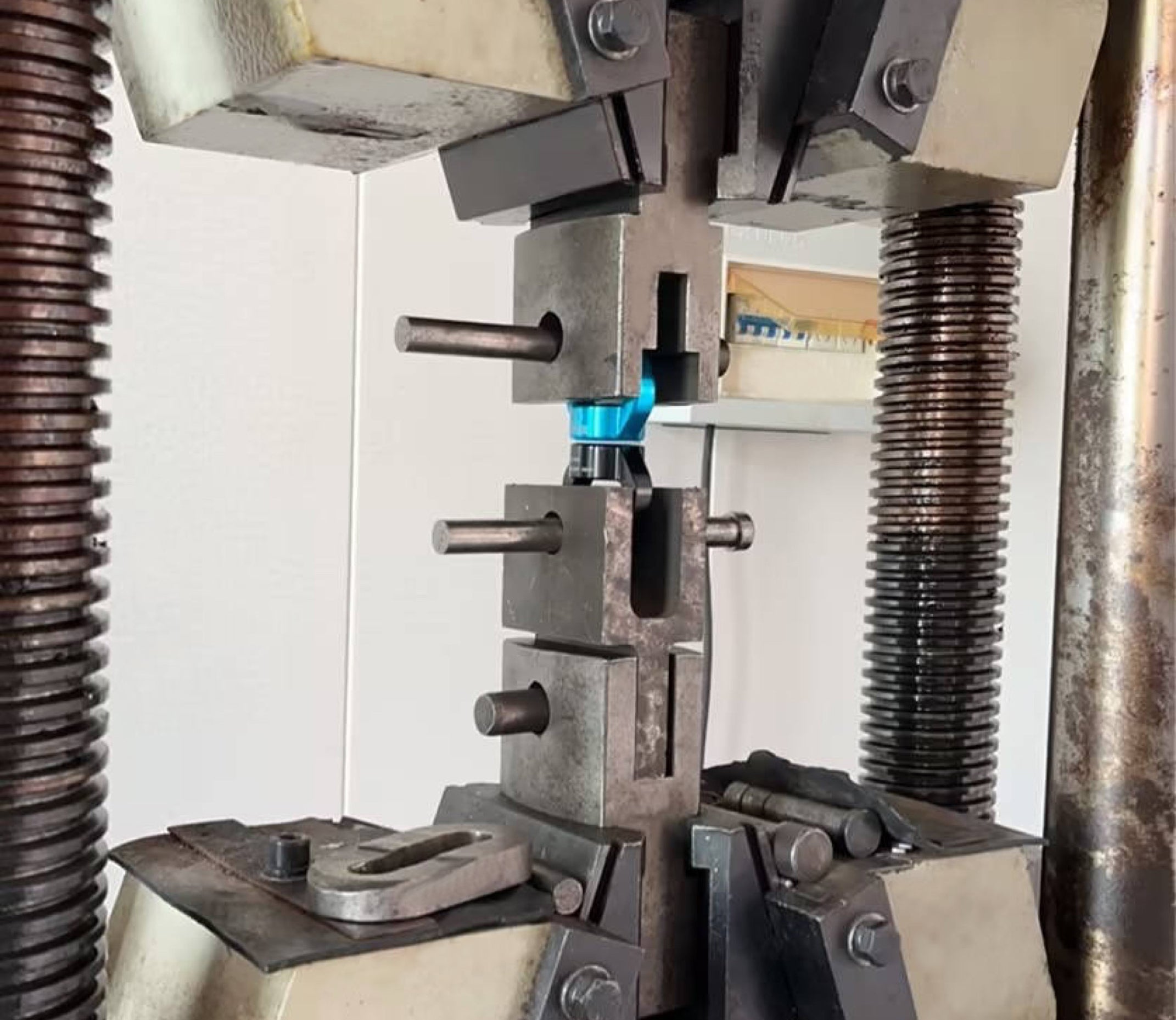

Tensile Stress Testing

The most pivotal test required for all rigging gear. It is used to ensure equipment is resilient under tension and can handle high dynamic loads exerted in aerial arts.

During this test, equipment undergoes rigorous tension tests within specialized machinery until it reaches its breaking point. These results meticulously quantify the force, measured in kilonewtons (kN), that each piece can withstand, ensuring safe load handling for aerial movements.

Each piece of gear is required to have the breaking strength marked on it in kN (1 kN = 225lb)

Step inside the lab.

Here's how your gear performed during its recent batch test.

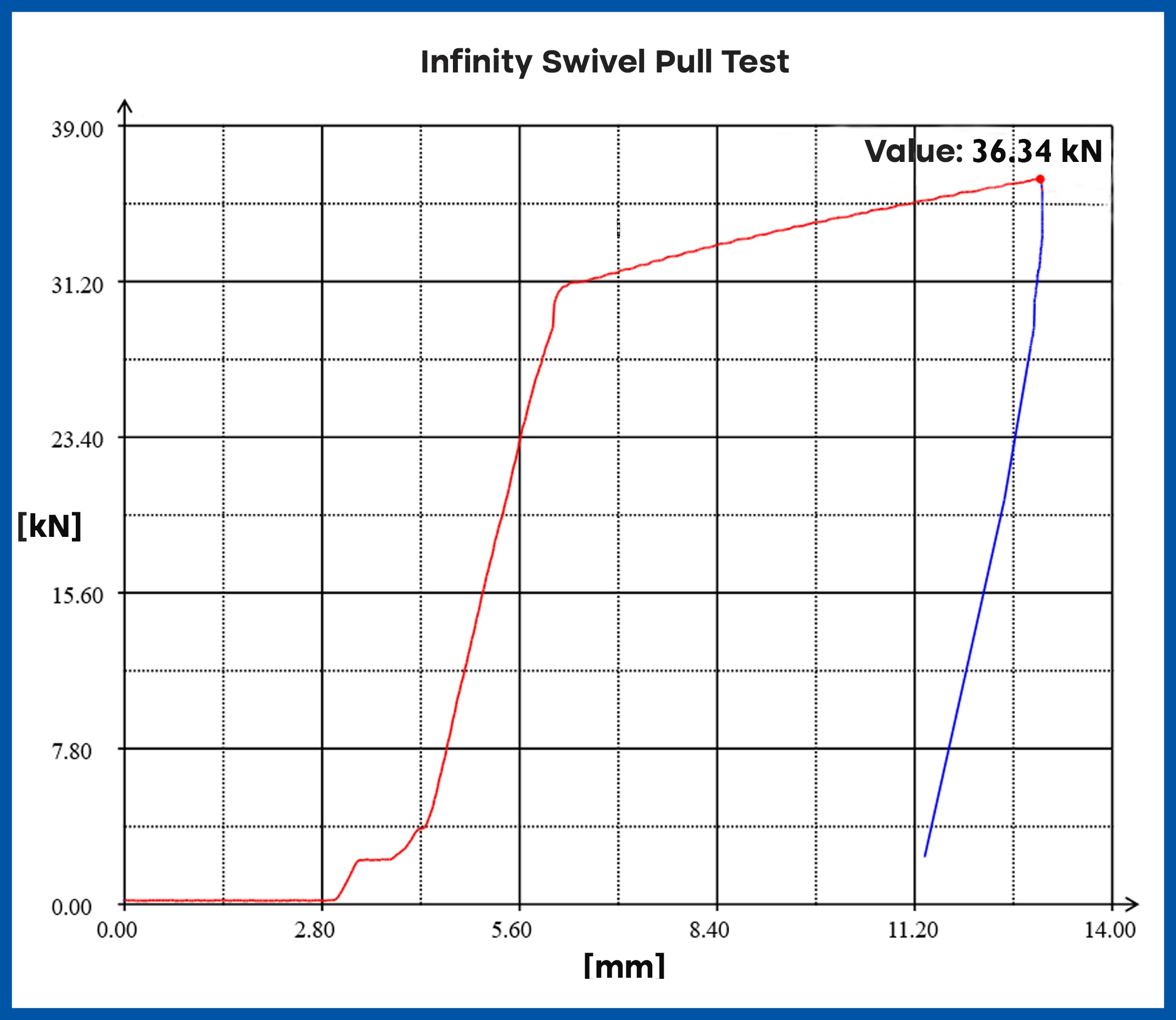

Infinity Swivel Tensile Strength Test

The infinity swivel is CE certified to the special provision PPE-R/11.135 which has components of EN12275:2013 tensile strength testing and EN354:2010 corrosion testing requirements. These standards ensure compliance with Mountaineering PPE requirements of performance and safety.

The infinity swivel exhibits an ultimate tensile strength of 36kN. However, we establish the swivel's strength rating at 30kN, as this aligns with its yield strength. The swivel has also passed the corrosion test meaning long lasting performance in even the most harsh environments.

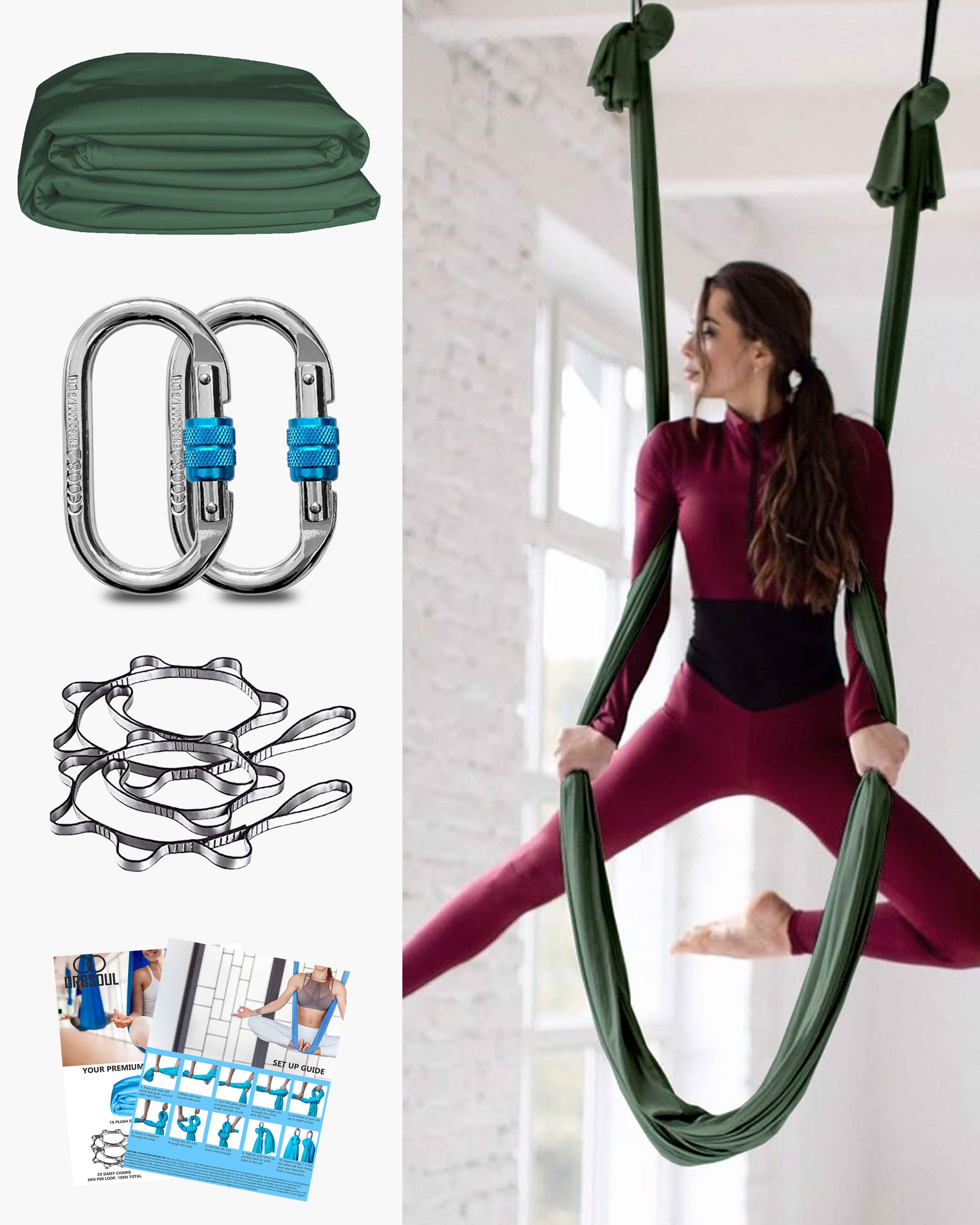

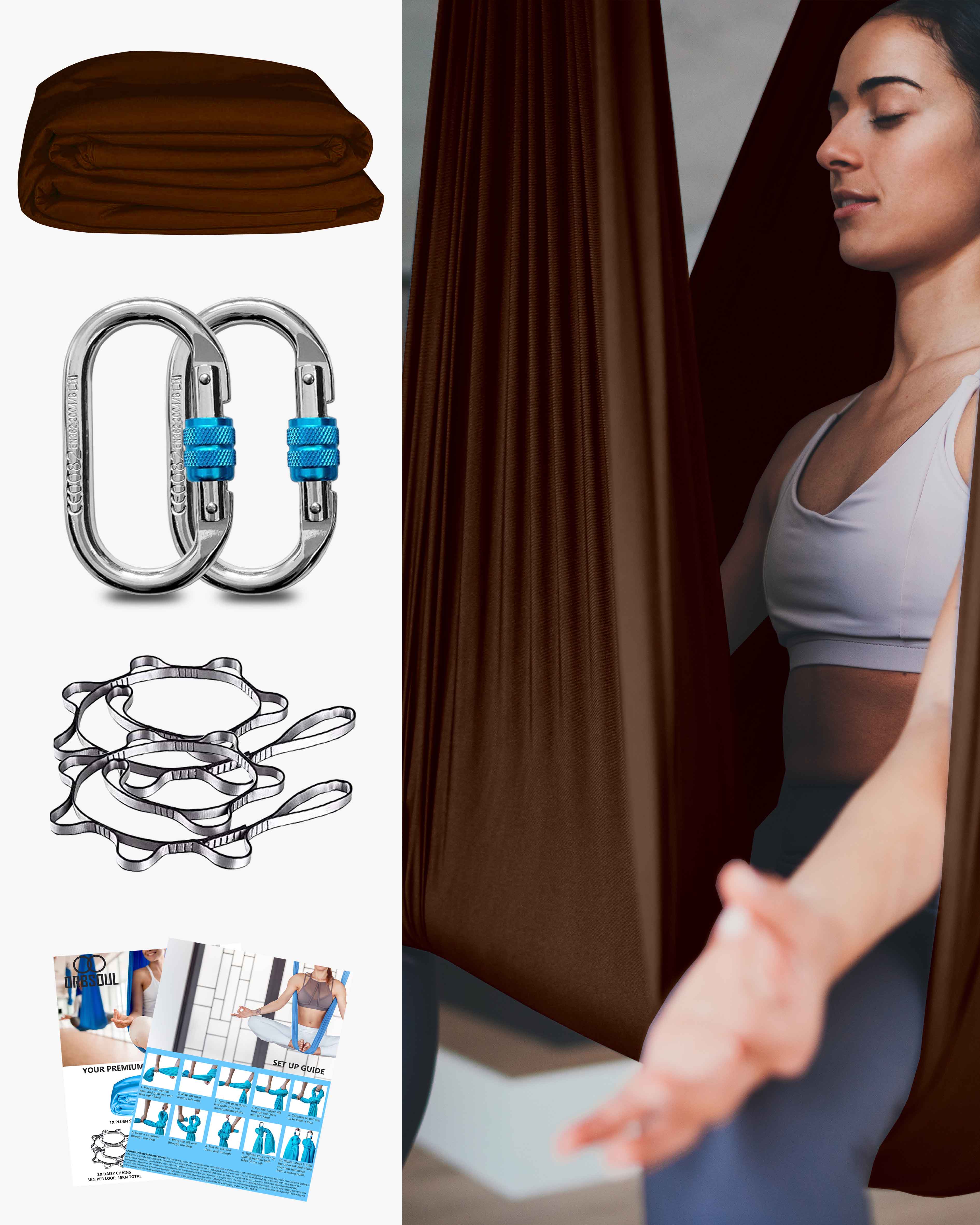

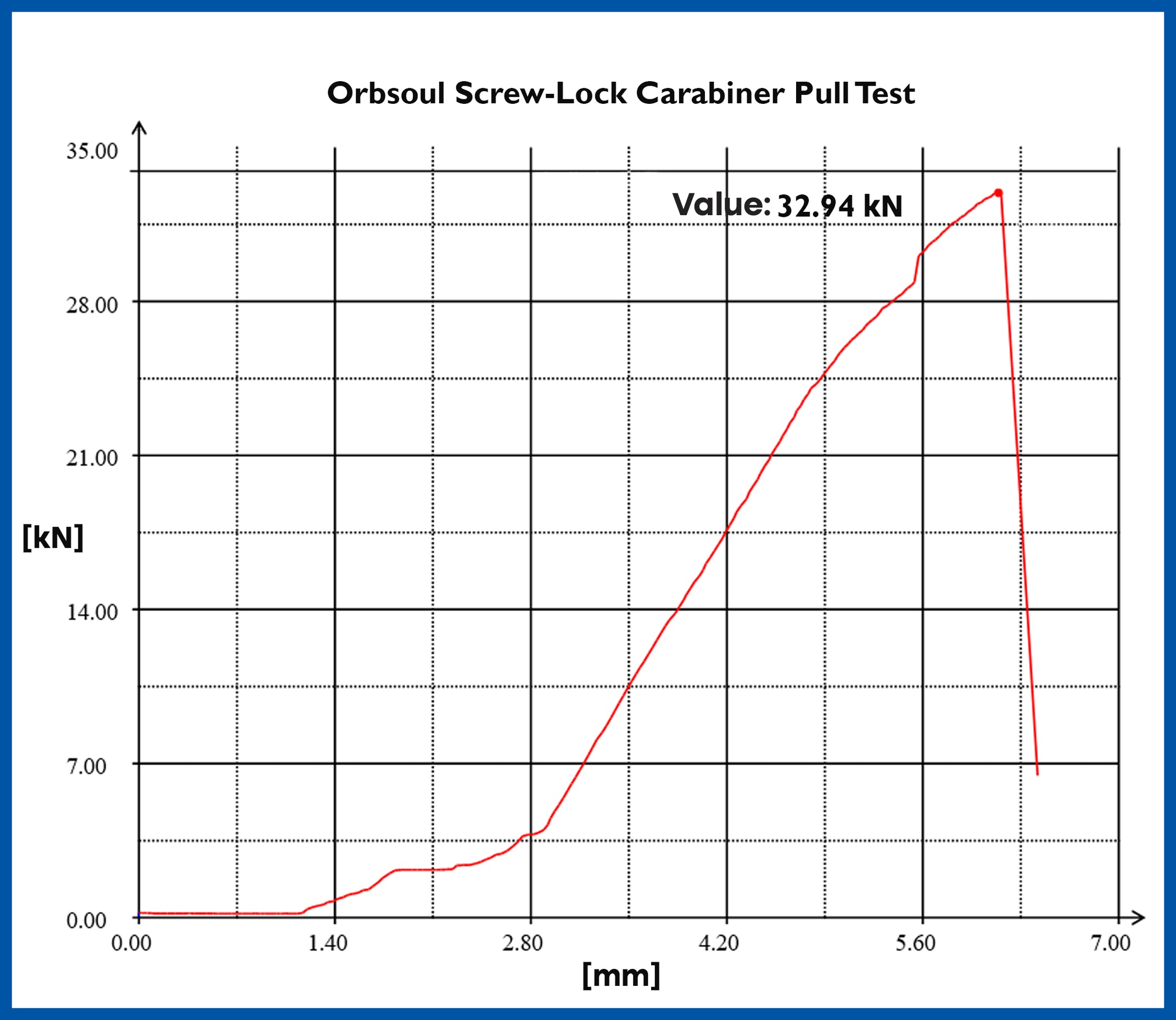

Screw-lock Carabiner Strength Test

Our screw-lock carabiners are CE certified to the special provision EN362:2004 which has components of tensile strength testing and corrosion testing requirements. These standards ensure compliance with Carabiner PPE requirements of performance and safety.

The Screw-lock Carabiner exhibits an ultimate tensile strength of 32kN. However, we establish the strength rating at 25kN, as this aligns with its yield strength. The carabiners also pass the corrosion test ensuring long lasting performance in even the most harsh evironments.

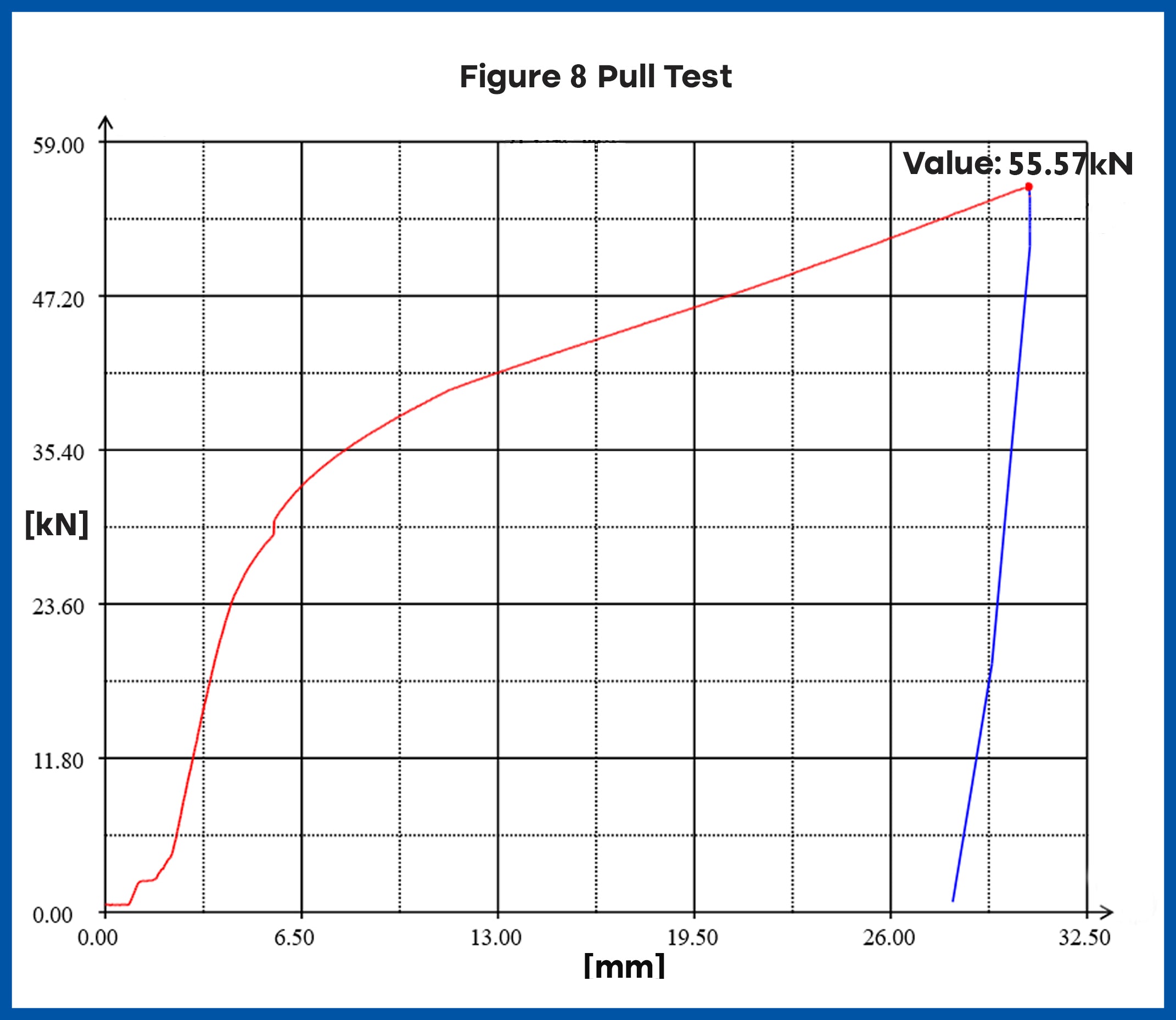

Balance 8 Descender Tensile Strength Test

The balance eight descender design is traditionally used in mountaineering for belaying or rappelling with a rope. Because of this, Traditional PPE standards for figure eights do not apply to the aerial arts. However, we do certify to the standard EN365 regarding marking and technical use as well as perform strength testing.

The Figure Eight Descender exhibits an ultimate tensile strength of 50kN.

Understanding the test and results

Tensile testing graph

A tensile testing graph illustrates the relationship between the applied force (stress) and the resulting deformation (strain) of a material. Typically, it begins with a linear region where stress and strain increase proportionally, known as the elastic region.

Beyond this, the graph exhibits plastic deformation, where the material undergoes permanent changes but can still return to some extent to its original shape.

Finally, it reaches a point of ultimate tensile strength, representing the maximum force the material can withstand before breaking.

The point at which the test subject enters the plastic deformation stage is known as the yield point or yield strength. This value (measured in kN) is what your gear is rated to and is marked on each piece of hardware.

If you've made it this far, congratulations! You are now well versed in batch break testing and understanding the results.

As our aerial rigging hardware is made and tested to EN standards of Personal Protective Equipment (PPE), CE certification is also an integral part of our processes.