Your Guide on Aerial Rigging Hardware—Testing and Certification

Learn about Safety Testing and Certification

Aerial arts is exhilarating, challenging, and truly MESMERIZING! It is your self expression unleashed in the most geniune and beautiful way, inspiring all who look up.

To have peace of mind during your time in air, you need reliable and safe gear that is independently and continuously tested. In relation to aerial arts, there is no specific regulatory or governing body specifying requirements for aerial equipment. Equipment such as carabiners and swivels fall under the category of Personal Protective Equipment (PPE) used in fall arrest systems. There are various governing bodies that have standards for PPE such as ANSI (American National Standards Institute), CSA (Canadian Standards Association) and CE (Conformité Européene).

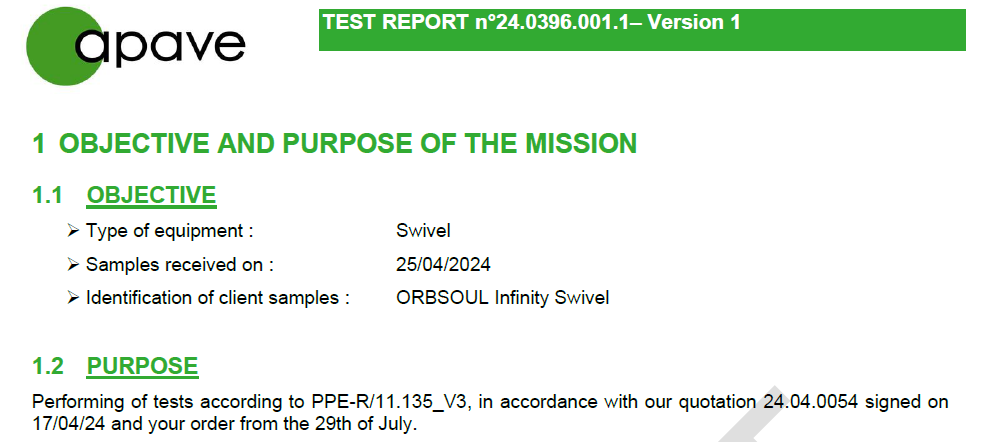

At Orbsoul, we choose CE certification as it is the most widely recognized for aerial arts equipment globally and has the strictest standards and testing protocols for equipment. Our manufacturing facilities work with Apave Group in France and SGS Testing in Finland, who test our equipment to the highest mountaineering standards, ensuring safety and quality.

Let's dive in and learn all about certification and the tests that are done to ensure your gear meets industry standards to keep you safe in the air.

CE Certification - What exactly is it?

CE, which stands for "Conformité Européenne," is a certification mark denoting conformity with health, safety, and environmental protection standards for all products sold within Europe. In essence, CE certification signifies that the product complies with essential health and safety requirements. If a product is CE certified a "CE" symbol is affixed on the product followed by the 4 digit notifying body number. Even though it is a standard originating from Europe, it is recognized worldwide for aerial arts.

What tests are done and how is it defined?

Aerial rigging equipment is categorized as Personal Protective Equipment (PPE) for fall protection and must adhere to EN standards developed collaboratively by experts across the industry. Testing for CE certification of PPE requires involvement from an approved Notifying Body. This ensures tests are done by reputable experts with proper lab equipment and provides an extra layer of assurance for product quality and user safety.

We partner with Apave Group in France, Notifying body number 0082.

Tensile Stress Testing

The most pivotal test required for all rigging gear. It is used to ensure equipment is resilient under tension and can handle high dynamic loads exerted in aerial arts.

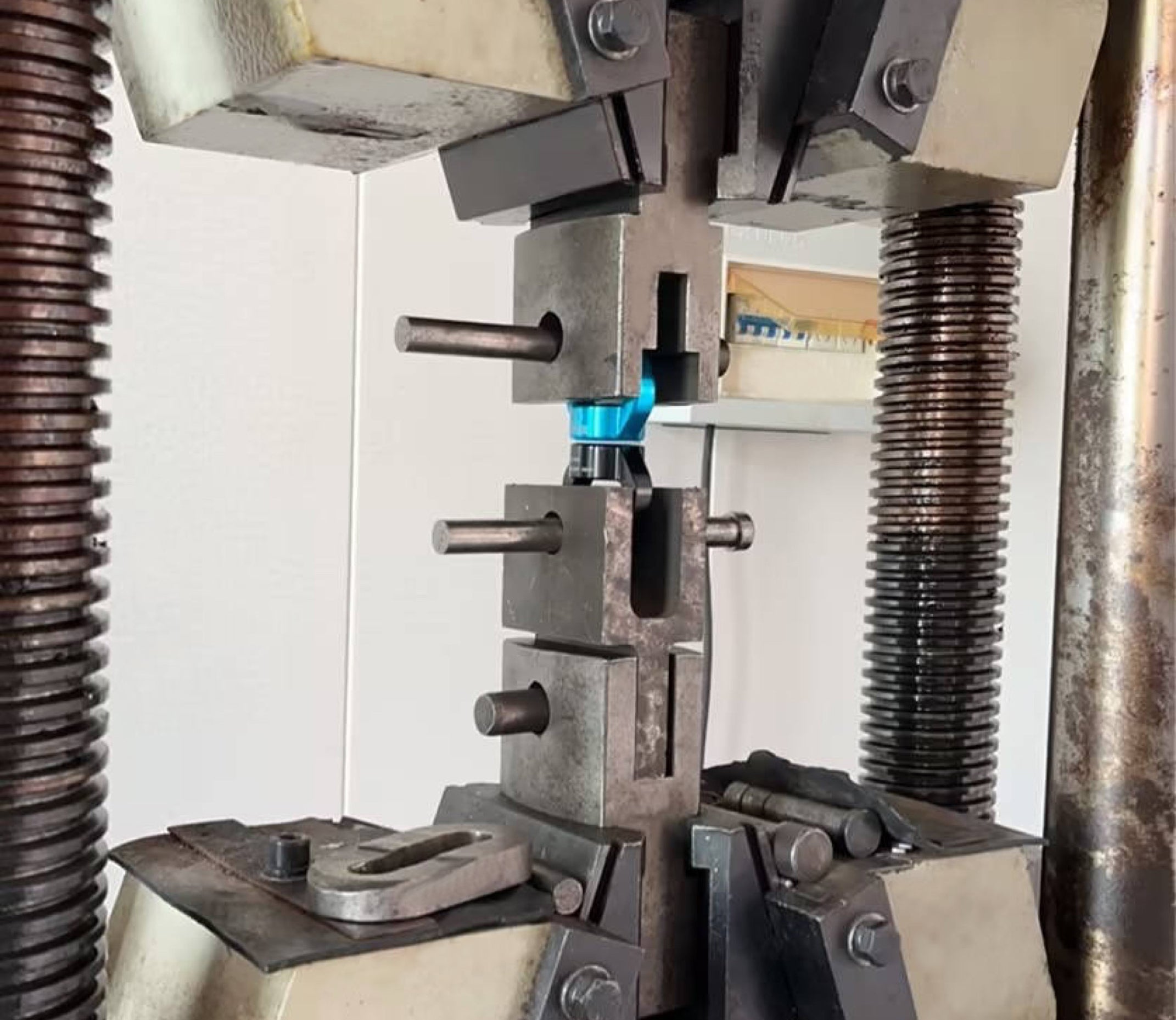

During this test, our gear undergoes rigorous tension tests within specialized machinery until it reaches its breaking point. These results meticulously quantify the force, measured in kilonewtons (kN), that each piece can withstand, ensuring safe load handling for aerial movements.

All components share a specific requirement as dictated in the standard EN365 which outlines instructions for use, maintenance, and marking.

Each piece of gear is required to have the breaking strength marked on it in kN (1 kN = 225lb) with instructions for use provided to users.

Corrosion Testing

Carabiners and swivels also undergo corrosion tests that evaluate the resilience of hardware against rusting in challenging environments.

As an example, take a look at one of our test reports from APAVE.

Testing report results for the infinity swivel showing conformity to tensile strength and corrosion resistance requirements.

EN Standards - For those who want the details

Fire and Ice Carabiners

EN362: Governs connectors such as carabiners used in aerial arts. The carabiner must pass the following tests:

- Various strength tests: Tensile strength, gate strength, and gate opening tests to ensure reliability and safety in preventing falls.

- Corrosion test: All metallic elements shall not show evidence of corrosion of the base metal.

- Marking: ‘kN’ value determined through testing with reference to the standard EN362.

- Instructions for use provided to customers

Infinity Swivel

PPE-R/11.135: A special provision combining several standards, governs swivels used in aerial arts. The swivel must pass the following tests:

- Tensile strength test: following applicable requirements of EN 12275:2013.

- Corrosion test: All metallic elements shall not show evidence of corrosion of the base metal

and swiveling shall still function after salt spray. - Marking: Marking: ‘kN’ value determined through testing with no reference to an EN standard.

- Instructions for use provided to customers

Balance Eight Descender

The balance eight descender design is traditionally used in mountaineering for belaying or rappelling with a rope. Because of this, Traditional PPE standards for figure eights do not apply to the aerial arts. However, we do adhere to the standard EN365 regarding marking and technical use as well as perform tensile strength testing to determine the safe load value.

Testing once is great, but how do we ensure ongoing quality control?

Great question. This is where we at Orbsoul take things a step further.

As mentioned, tensile strength testing is the most important test in ensuring gear is strong enough to handle dynamic aerial loads such as drops.

To ensure our manufacturing process produces consistent high quality gear we tensile strength test (Break Test) every batch we make.

If you've made it this far, congratulations! You are now well versed in aerial rigging certification, testing standards and their importance in keeping aerialists safe in the air. Before you go, we want to invite you into the lab to see the strength testing of your aerial rigging hardware in action.

Step inside the lab.

Here's how your gear performed during its recent batch test.

What is Batch Break Testing?

Batch break testing involves testing samples from each batch produced to determine their minimum breaking strength (MBS). This testing is important for ensuring the safety and reliability of the rigging equipment used in aerial arts and performances.

During batch break testing, a sample of the rigging components from the batch is subjected to controlled tension until it first deforms (breaks). The breaking strength of each component is recorded, and the results are used to determine if the batch meets the required safety standards.

Batch break testing helps identify any weaknesses or defects in the rigging components that could lead to failure during use. By regularly testing batches, we uphold our initial certification standards and continuously monitor our manufacturing process, ensuring the ongoing safety of our rigging equipment for aerialists.

How is Minimum Breaking Strength (MBS) determined?

Mechanical Tensile Strength Testing is a crucial process used to determine the maximum load a material or structure can withstand before deforming or breaking. It involves subjecting a sample of a component to gradually increasing tension until it reaches deformation (breaking point). This testing method provides valuable data regarding the material's durability, resilience, and documents the MBS (minimum breaking strength).

Why do we require this?

- Safety Assurance: Aerial silks and rigging hardware are subjected to considerable tension and stress during performances or training sessions. Ensuring that these materials and components can withstand the expected loads without failure is paramount to guarantee the safety of aerialists and performers.

- Performance Optimization: By knowing the mechanical tensile strength of aerial silks and rigging hardware, we can design products that meet or exceed the required safety standards while also optimizing performance. Understanding the limits of materials allows for the development of equipment that can withstand rigorous use and demanding maneuvers without compromising safety.

- Quality Control: Mechanical tensile strength testing serves as a quality control measure for both aerial silks and rigging hardware. At Orbsoul, by testing samples from each production batch, we ensure continued consistency, strength and reliability in our products. Identifying any weaknesses or variations in materials early on helps prevent potential accidents or failures in real-world usage.

- Regulatory Compliance: In many jurisdictions, there are specific regulations and standards governing the design and manufacturing of equipment used in aerial arts and performances. Mechanical tensile strength testing provides empirical data that can be used to demonstrate compliance with these standards, thereby ensuring legal and regulatory obligations are met.

- Risk Mitigation: A thorough understanding of the mechanical properties of rigging hardware allows for informed risk assessment and mitigation strategies. By identifying potential failure points or weak spots, measures can be taken to reinforce or redesign equipment to minimize the risk of accidents or injuries during aerial performances.

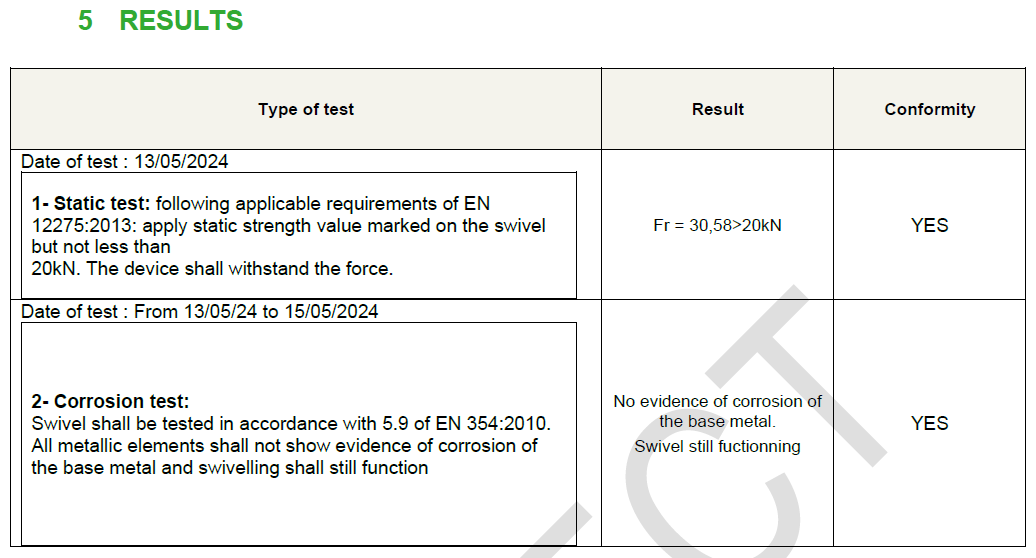

Infinity Swivel Tensile Strength Test

The infinity swivel is tested to the special provision PPE-R/11.135 which has components of EN12275:2013 tensile strength testing and EN354:2010 corrosion testing requirements. These standards ensure compliance with Mountaineering PPE requirements of performance and safety.

The infinity swivel exhibits an ultimate tensile strength of 36kN. However, we establish the swivel's strength rating at 30kN, as this aligns with its yield strength. The swivel has also passed the corrosion test meaning long lasting performance in even the most harsh environments.

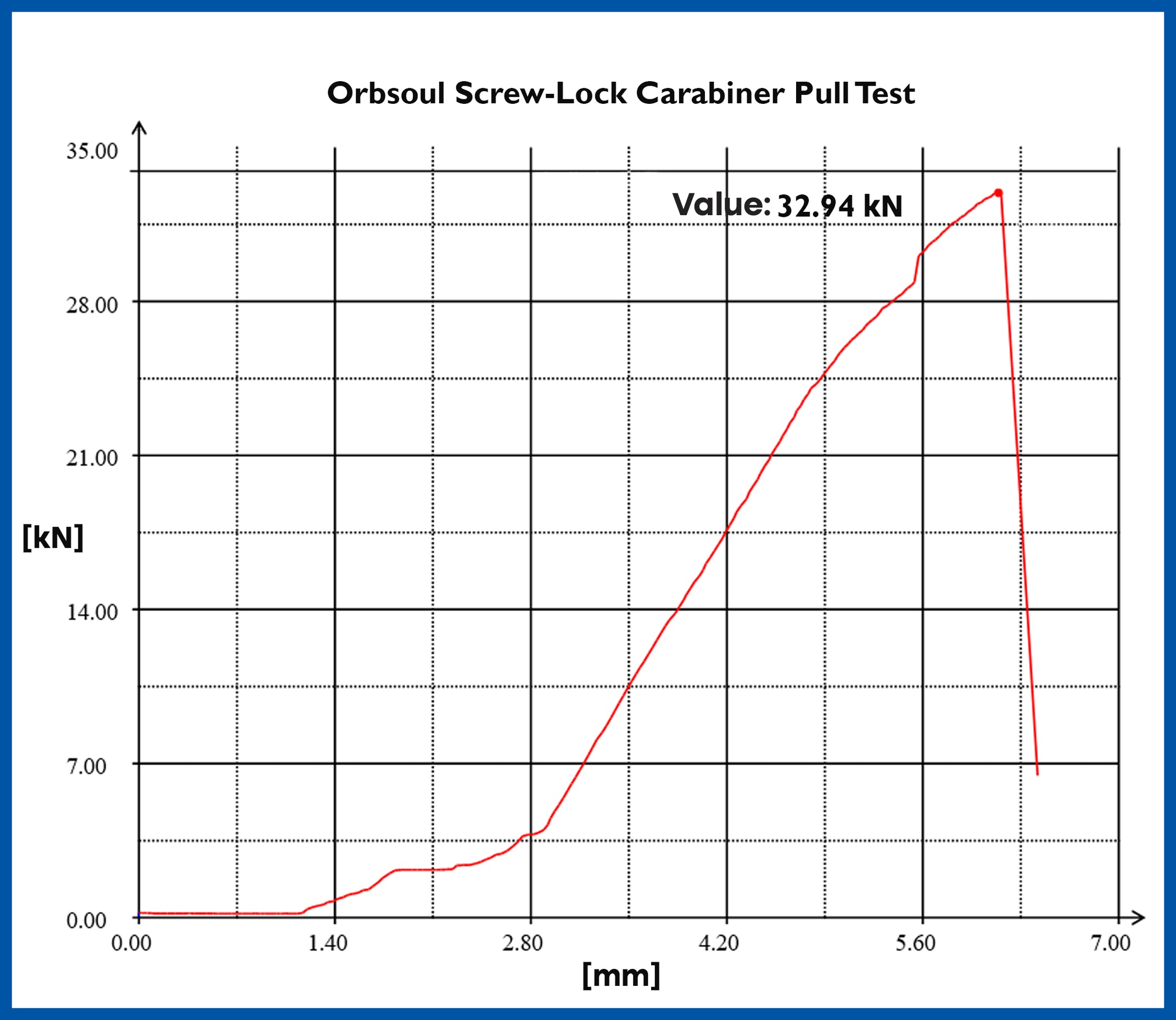

Screw-lock Carabiner Strength Test

Our screw-lock carabiners are tested to the EN standard EN362:2004 which has components of tensile strength testing and corrosion testing requirements. These standards ensure compliance with Carabiner PPE requirements of performance and safety.

The Screw-lock Carabiner exhibits an ultimate tensile strength of 32kN. However, we establish the strength rating at 25kN, as this aligns with its yield strength. The carabiners also pass the corrosion test ensuring long lasting performance in even the most harsh environments.

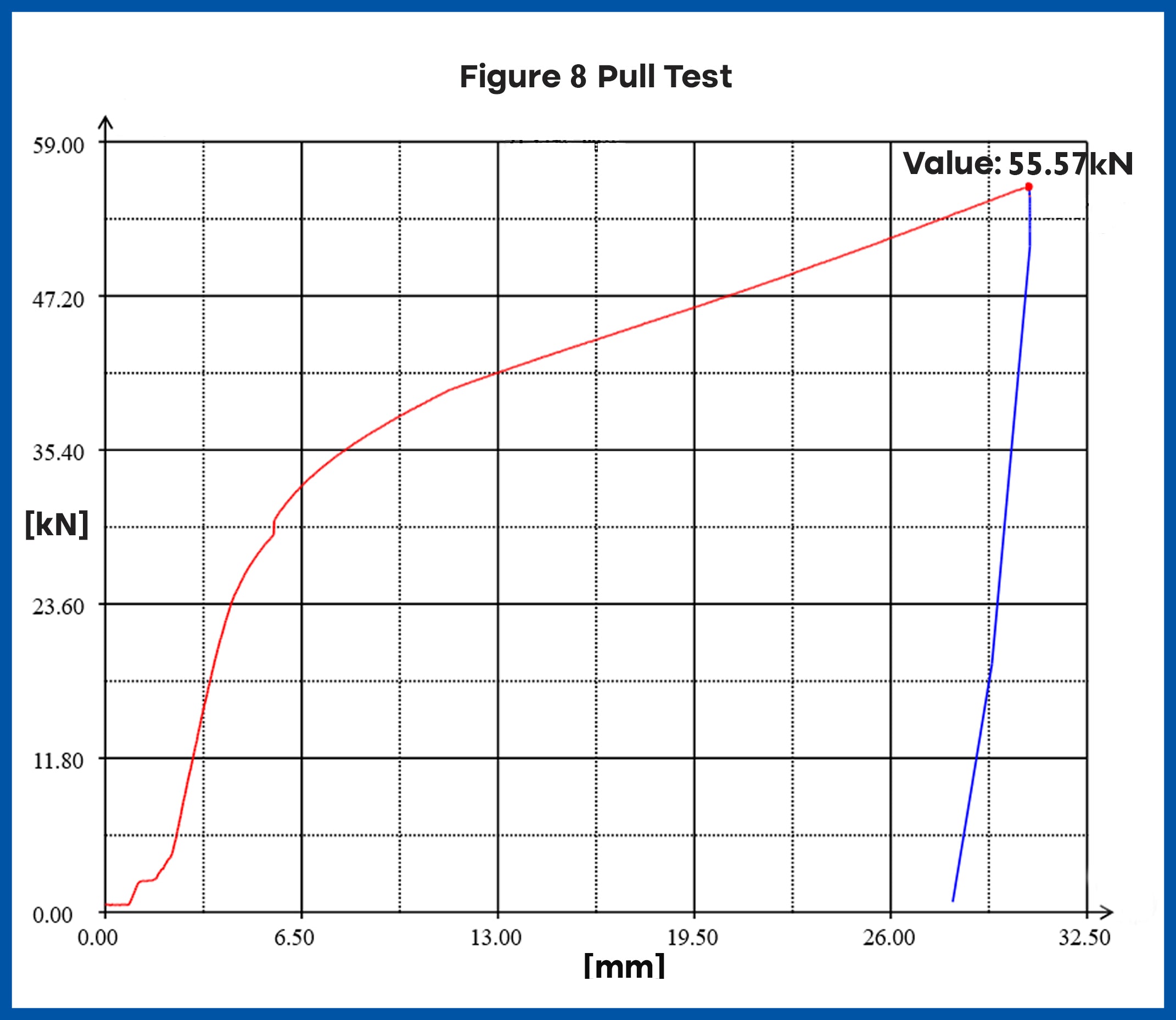

Balance 8 Descender Tensile Strength Test

The balance eight descender design is traditionally used in mountaineering for belaying or rappelling with a rope. Because of this, Traditional PPE standards for figure eights do not apply to the aerial arts. However, we do certify to the standard EN365 regarding marking and technical use as well as perform strength testing.

The Figure Eight Descender exhibits an ultimate tensile strength of 50kN.

Understanding the test and results

A tensile testing graph illustrates the relationship between the applied force (stress) and the resulting deformation (strain) of a material. Typically, it begins with a linear region where stress and strain increase proportionally, known as the elastic region.

Beyond this, the graph exhibits plastic deformation, where the material undergoes permanent changes but can still return to some extent to its original shape.

Finally, it reaches a point of ultimate tensile strength, representing the maximum force the material can withstand before breaking.

The point at which the test subject enters the plastic deformation stage is known as the yield point or yield strength. This value (measured in kN) is what your gear is rated to and is marked on each piece of hardware.